Metal Roofs 101

9 min read

Before we get into the many benefits and facts regarding metal roofs and their ecological benefits let’s talk about the elephant in the room: aesthetics. There is an undeniable modernity associated with metal as a roofing material. There are endless instances of brutalist modern boxes that utilize metal roofs as a default. That is a look only adored by some. Thus, one of the goals of the following paragraphs is to dispel the defacto image in your mind of how and where metal roofs can be used. From ranch and craftsman to victorians and tudors and everything else, metal can be utilized as a wonderful tool to add color, strength, character and a refreshed aesthetic. So everyone, with me, close your eyes, take a deep breath and wipe those modern box images out of your mind. There, feel that? Clean slate… now you are ready to re-envision metal as a roofing material!

Durability

Metal roofs are known for their exceptional durability and longevity. They can last two to three times longer than traditional asphalt shingle roofs, reducing the frequency of replacement. This extended lifespan helps to conserve resources, reduce waste and save money in the long run. The choice of metal plays a crucial role in the durability of a metal roof. Commonly used metals include steel, aluminum, copper, and zinc. Each metal has its own inherent properties and resistance to corrosion, impact, and weathering. Galvanized steel and aluminum alloys are popular mainstream options due to their strength and rust resistance.

Let’s talk metallurgy for a minute. Galvanization involves applying a protective zinc coating to the surface of the metal. This coating acts as a sacrificial layer that corrodes in place of the underlying metal, effectively shielding it from rust and corrosion. The zinc coating acts as a barrier that slows down the corrosion process. Even if the coating gets scratched or damaged, the remaining intact zinc continues to protect the exposed area. This characteristic ensures that small scratches or imperfections in the coating do not lead to rapid rusting. Galvanized metal provides a form of cathodic protection. Zinc, being more reactive than steel, acts as an anode and sacrifices itself to protect the steel. In the presence of moisture or other corrosive substances, any corrosive attack targets the zinc layer first, sparing the underlying steel from rusting. If the zinc coating gets damaged, it can self-heal through a process called galvanic or self-corrosion. The surrounding zinc sacrifices itself to repair any exposed areas by forming zinc oxide or zinc carbonate, which acts as a barrier against further corrosion. All of this adds to the longevity of the roof as the zinc coating on galvanized metal is relatively thick, providing long-term protection. It is important to note that the thickness of the coating can vary depending on the application and the specific galvanizing process used.

Another important durability component is the thickness of the metal roof. The gauge of the metal varies depending on regional application, weather and protection needs. Keeping those tenets in mind should help guide your purchase. Here is the basics. The gauge measurement system for metal roofing typically ranges from 22 - 29 gauge, with lower gauge numbers indicating thicker metal. Here are the common gauge thicknesses for metal roofs and their corresponding ratings:

29 Gauge: This is the thinnest commonly used gauge for metal roofing. It is approximately 0.0142 inches (0.36 mm) thick. 29 gauge metal roofs are lightweight and less expensive but may be more prone to denting and may have slightly reduced durability compared to thicker gauges. They are often used in residential applications.

26 Gauge: This gauge is thicker than 29 gauge, with a thickness of approximately 0.0187 inches (0.48 mm). 26 gauge metal roofs provide better durability and resistance to denting. They are commonly used in both residential and commercial applications.

24 Gauge: Considered a heavy gauge, 24 gauge metal roofs are approximately 0.0239 inches (0.61 mm) thick. They offer enhanced strength, durability, and resistance to impacts and dents. 24 gauge metal roofs are suitable for various applications, including residential, commercial, and industrial buildings.

22 Gauge: This is the thickest gauge commonly used for metal roofing. 22 gauge metal roofs are approximately 0.0299 inches (0.76 mm) thick. They provide exceptional strength, durability, and resistance to impacts. 22 gauge roofs are typically used in applications where maximum durability is required, such as industrial and commercial buildings.

Hurricane, heavy weather and tornado prone regions should utilize gauges 24 and 22 as the default minimum thickness for best protection.

It's worth noting that over time, the zinc coating may naturally weather and develop a patina. This patina, typically gray in color, does not affect the protective properties of the galvanized metal and actually provides an additional layer of defense against corrosion.

Overall, galvanized metal's resistance to rust is due to the protective zinc coating, which acts as a physical barrier, sacrificial layer, and self-healing mechanism to safeguard the underlying metal from corrosion.

Energy efficiency

Metal roofs have excellent energy-saving properties. This is primarily due to their natural ability to reflect a significant amount of solar radiation, reducing heat absorption and the need for air conditioning during hot summers. This reflective property can lead to lower energy consumption and reduced greenhouse gas emissions.

Light-colored metal roofs, particularly those with reflective coatings, can significantly reduce the amount of heat absorbed by the roof compared to darker roofs. The exact amount of heat diverted depends on various factors such as the color, reflectivity, insulation, and the local climate. The motivation behind encouraging lighter-colored roofs is primarily related to reducing the urban heat island effect and improving energy efficiency in buildings. The urban heat island effect refers to the phenomenon where urban areas experience higher temperatures compared to surrounding rural areas due to the absorption and retention of heat by buildings, roads, and other urban infrastructure. Dark-colored roofs, especially in sunny climates, can absorb a significant amount of solar radiation, leading to higher heat buildup in buildings and increased cooling energy demands.

In general, light-colored or reflective metal roofs can reflect a significant portion of solar radiation, reducing heat absorption. This helps to keep the roof and the underlying building cooler, resulting in less heat transfer to the interior spaces. As a result, the demand for air conditioning can be reduced, leading to energy savings and lower cooling costs. This cost reduction should be included in the calculus of metal roof selection as the initial costs of metal roofs are more than other roofing types.

The reflectivity of a roof is measured by its Solar Reflectance Index (SRI), which quantifies the ability of the material to reflect solar heat. Light-colored metal roofs, especially those with high SRI values, can reflect a substantial amount of solar radiation, often exceeding 70% reflectance. This high reflectivity contributes to keeping the roof surface cooler and reducing the overall heat gain in the building.

This has has reached a tipping point in Australia with city officials of Sydney moving to ban dark roofs as they push to net zero emissions by 2050. Speaking to the Committee for Sydney, planning minister Rob Stokes foreshadowed the policy switch to ensure all new housing has light-coloured roofing.

He said recent University of NSW research commissioned by the federal government found Sydney’s ambient temperatures could be reduced by up to 2.4C if dark roofing was ditched across the city. A light coloured roof could reduce temperatures inside the home by up to 10 degrees during a heatwave.

Details pulled from The Guardian

“This would have an enormous impact on the urban heat island effect in our city, and I will be asking the Department of Planning to implement this as part of our Net Zero Cities approach”

It's worth noting that the specific heat diversion achieved by a light-colored metal roof can vary based on other factors like insulation levels, roof design, geographic location, and local climate patterns. Additionally, the impact on cooling energy savings will depend on the overall building design and efficiency, including insulation, ventilation, and HVAC systems.

If you are considering installing a light-colored metal roof, consulting with roofing professionals or energy experts in your area can provide more precise information on the expected heat diversion and potential energy savings for your specific circumstances.

Recyclability

Metal roofs are highly recyclable at the end of their lifespan. Unlike asphalt shingles, which often end up in landfills, metal roofs can be completely recycled into new metal products. This recycling process helps conserve natural resources and reduces the demand for new raw materials. This regenerative process follows a general flow of removal > sorting > cleaning > shredding > melting > purification > casting > distribution & reuse. The recycled metal, in the form of ingots or other shapes, is distributed to manufacturers who can utilize it to produce various metal products. These can include new metal roofs, construction materials, automotive parts, appliances, and more.

The regenerative nature of recycling metal roofs causes valuable resources to be conserved, energy saved, and the environmental impact associated with mining and manufacturing new metal is reduced.

Reduced weight

The lighter weight of metal roofs can offer several advantages. With an average per square foot weight that is 50% less than a traditional asphalt shingle it puts less stress on the roof structure, reducing the structural load on the building which can be beneficial for both new constructions and retrofitting projects and potentially lead to cost savings during construction. It may also result in cost savings during installation since less structural reinforcement may be required. Additionally, the reduced weight can make transportation and handling of metal roofing materials easier and more efficient resulting in lower energy consumption during delivery. This has a positive impact on the total cost of the product from a carbon emissions standpoint.

Rainwater harvesting

Metal roofs are excellent for rainwater harvesting. The smooth surface of the metal allows rainwater to flow easily, and metal roofs can be designed to direct water into collection systems. Harvesting rainwater for various uses like irrigation reduces the strain on local water supplies.

Water catchment properties

Smooth surface: Metal roofs have a smooth surface that allows rainwater to flow easily. Compared to other roofing materials with textured surfaces, such as asphalt shingles.

Sloped design: Metal roofs are typically designed with a slope to promote proper drainage. This helps rainwater quickly and effectively move towards the gutters or collection points, reducing the chance of water pooling or stagnant areas on the roof.

Durability and cleanliness: Metal roofs are durable and resistant to moss, algae, and fungal growth, which can contaminate collected rainwater. The smooth surface of metal roofs makes it easier to maintain a clean and uncontaminated rainwater collection system.

Compatibility with gutters and downspouts: Metal roofs are compatible with gutter systems, allowing rainwater to be efficiently collected and directed to storage tanks or other rainwater harvesting systems.

Limited chemical leaching: Compared to some other roofing materials, metal roofs have limited chemical leaching. This is beneficial for rainwater quality, as it reduces the chances of harmful substances or contaminants being introduced into the harvested rainwater.

No matter the material when collecting rainwater from a metal roof, it is essential to consider proper filtration and storage methods. This can include using screens or filters to remove debris and sediments, and employing a storage tank or cistern to store the harvested rainwater for later use, such as irrigation or non-potable water needs.

Consulting with rainwater harvesting experts or professionals familiar with local building codes and regulations can provide guidance on the specific requirements and best practices for rainwater harvesting systems in your area. That said, we are a huge fan Blue Barrel Systems for they revolutionary approach to democratizing this process on any budget with existing resources that are being diverted from landfills.

Fire resistance

Metal, whether it is steel, aluminum, copper, or zinc, is a noncombustible material. It does not burn, ignite, or contribute to the spread of fire. This characteristic makes metal roofs inherently fire-resistant.

Class A Fire Rating: Metal roofs often have a Class A fire rating, which is the highest rating for fire resistance in building materials. This rating indicates that the roof assembly can withstand severe fire exposure and has the highest level of fire protection.

Protection Against Ember Attack: During wildfires, one of the main causes of structure ignition is ember attack, where wind-blown embers can land on a roof and ignite combustible materials. Metal roofs provide a barrier against ember attack since they do not provide fuel for the fire and are not susceptible to ember ignition.

Reduced Fuel Load: Metal roofs do not accumulate debris, such as leaves, twigs, or other flammable materials, as easily as other roofing materials like wood shingles or asphalt. By having a reduced fuel load on the roof, the risk of fire ignition is further minimized.

Insulation Separation: Metal roofs are installed with a layer of insulation or airspace beneath them. This separation helps to prevent the transfer of heat from the roof surface to the underlying structure. By limiting heat transfer, metal roofs reduce the risk of fire spreading from the roof to the interior of the building.

Protection Against Lightning: Metal roofs do not attract lightning strikes, contrary to a common misconception. In the event of a lightning strike, the metal roof acts as a conductor, safely dispersing the electrical energy throughout the roof structure and into the ground, reducing the risk of fire compared to other roofing materials.

While metal roofs offer significant fire resistance, it's important to note that fire safety involves more than just the roof. The overall fire resistance of a building depends on various factors, including the materials used in the walls, windows, and other components, as well as the presence of fire-rated insulation and proper fire containment measures.

Consulting local building codes and regulations, as well as following recommended fire safety practices and guidelines, is crucial for ensuring comprehensive fire protection in buildings.

Pest resistance

Metal roofs are less susceptible to damage from pests such as termites or rodents, which can cause significant harm to traditional roofing materials. This reduces the need for chemical treatments or pest control measures. Their smooth surface does not provide easy footholds for pests such as rodents, squirrels, or raccoons. These animals find it difficult to climb or dig, reducing the likelihood of them accessing the roof. Metal roofs are typically installed with overlapping panels and sealed tightly, leaving minimal gaps or openings. This makes it difficult for pests to find entry points into the structure. Insects like termites or ants, for example, are less likely to infest metal roofs compared to wooden structures due to their lack of easy infestation. Metal roofs often have reflective coatings or finishes that help to reflect sunlight and heat. This can deter pests that are sensitive to high temperatures or seek shelter in warmer environments.

Different metal roof types and aesthetics

Standing Seam Metal Roof: The most popular type of metal roof. It features vertical metal panels with raised seams that interlock to create a continuous and sleek appearance. Standing seam roofs offer excellent water shedding capabilities and are known for their durability and resistance to high winds.

Corrugated Metal Roof: Corrugated metal roofs have wavy or ribbed panels that provide strength and rigidity. They are often used in agricultural, industrial, and commercial applications. Corrugated roofs are lightweight, cost-effective, and offer good resistance to weather conditions. Lately, this material is having a resurgence by reinvisioning it on any structure. The addition of corrugation to your roofline ads touches off old and new. On certain structures it can even add a modern aesthetic to a traditional silhouette. Lastly, the corrugation pattern helps to diffuse light reflection dramatically better than the flat metal options. The natural wave of the steel creates airflow between the metal and the roof substrate enabling for the dispersion of heat and easy drying out of any moisture.

Metal Shingle Roof: Metal shingle roofs mimic the appearance of traditional roofing materials like asphalt shingles, wood shakes, or clay tiles. They are available in various styles, including interlocking panels or individual shingles. Metal shingle roofs offer the durability and longevity of metal with the aesthetic appeal of traditional roofing materials.

Metal Tile Roof: Metal tile roofs replicate the look of ceramic or concrete tiles but with the lightweight and durability advantages of metal. They can be made to resemble various tile profiles, such as Spanish or Mediterranean styles. Metal tile roofs provide a visually appealing option while offering the benefits of a metal roof.

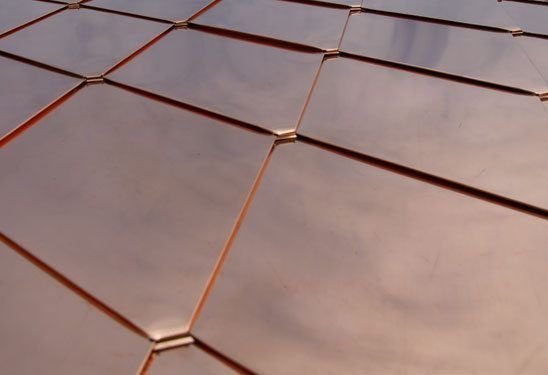

Copper Roof: Copper roofs are distinctive and known for their natural beauty. Over time, copper develops a unique patina that adds to its visual appeal. Copper roofs are durable, weather-resistant, and have a long lifespan. They are often used in architectural or high-end residential applications.

Zinc Roof: Zinc roofs are valued for their longevity, corrosion resistance, and distinctive appearance. Over time, zinc develops a protective layer that helps it withstand the elements and gives it a weathered and attractive patina. Zinc roofs are commonly used in contemporary or modern architectural designs.

Aluminum Roof: Aluminum roofs are lightweight, corrosion-resistant, and easy to work with. They are available in various styles and profiles, offering versatility and durability. Aluminum roofs are suitable for both residential and commercial applications.

Each type has its own unique characteristics, aesthetic options, and suitability for different applications. When choosing a metal roof, it's essential to consider factors such as the climate, building design, desired appearance, and budget to select the most suitable type for your specific needs.

For our little farm house with steep gables and baton walls we went with the timeless corrugated steel in natural. This gave us an elevated look to a traditional structure and can be referenced below (not our house) by the amazing work of Bruce Damonte Architecture.

Every decision when building or renovating a structure has a number of factors to consider from aesthetics, longevity, structural integrity and most of all cost. We hope that we were able to deconstruct the preconceived notions on what has been the metal roof vision and allow you to reinvision your next project with a sustainable metal top hat. No matter the building style there is a light colored metal roof for it. Cheers to your new 50 year roof!